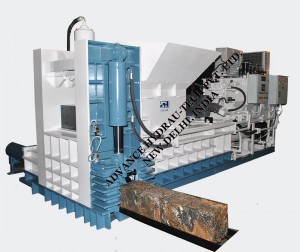

The use of aluminum cans is seen frequently in the market. Cold drinks, processed food, fruits, syrups and condensed milk cream are packed in the aluminum cans which are after use thrown into the garbage. This is a kind of garbage which cannot be settled in the pits or an open land as they could not be degraded easily on its own, until certain processing machinery is used to compact or bale it. With the use of hydraulic baling press aluminum cans compactor machine, the recycling process is achieved. However, the ‘Aluminum Can’ Processing Benefits are listed below which will encourage you to recycle them rather than throwing them in the garbage-

Conservation of the energy

By using compactor and baling hydraulic machinery, industries are recycling metallic scrap. The energy used in degrading them is very less in comparison to its manufacture. When metals are extracted from the virgin sources, then loads of energy consumption is required because of which industries believe in recycling the used cans and then utilizes the same recycle metal in the production of new products. the wastage of virgin ore is not a good idea at all.

95% aluminum metal is conserved by the process of scrap crushing and baling, 90% copper is extracted and 60% other metals such as iron and steel.

Conservation of natural resources

When you are using the recycled aluminum r other metallic products, then automatically you are contributing a hand in conservation of natural resources. This is one of the biggest benefit industries and mankind is achieving by aluminum cans processing.

Eco friendly atmosphere

The reduction of greenhouse gas is observed since recycling plants and hydraulic compactor machineries are used. However, 300 to 500 million tons of greenhouse gas emission is prevented each year after the aluminum cans processing. Instead of usingvirgin ores, recycled metals are better and they help in maintaining the ecology.

Benefits to the economy

When recycling is done on a tremendous speed and on frequent basis in every part of the nation, then employment opportunities comes forth and directly or indirectly it brings the economy on rise. The waste industry is not able to contribute income to the economy rather aluminum and other metallic cans processing system is giving much more benefits.

Development of the new products

The production cost of the products reduces when waste metals are recycled and after compacting used by the industries for developing new projects. The processed cans extracts metals up to 60% by which other new cans are produced. This is like a chain of processing due to which both mankind as well as industries is getting chief benefits.

In order to achieve an eco friendly and pollution free atmosphere, you must buy a crusher machine or baler for extracting the useful metals and crushing them into sheets for the reuse. Now government of various nations is regulating companies who manufacture steel or any other metallic product to install a recycle plant in which compactor, shearing machine, baler Shredder etc. are included.