The scrap is the junk or the waste materials which can be obtained from the business as well as the residential environment. The metals or the scraps are mainly the parts of old vehicles, business supplies, etc. The scrap processing machine is an equipment which is used in the process of scraping metal or the scraps.

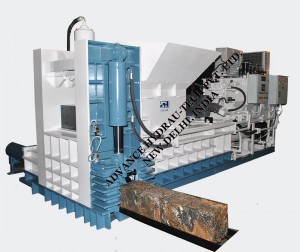

Scrap Processing Machine

Why to Scrap Processing Machine?

The scrap is no doubt piece of junk but we need to believe it that those unwanted metals have some monetory value of their own. These pieces of the scraps are taken to a junkyard where they are processed and melted by using the scrap processing machine. After that the molten metal is again used in making of some other things. This in one way that promotes the idea of recycling.

The basic facts about Scrap Processing Machine

The equipments used for processing of the scrap and not only big but has a very strong build. These equipments are prepared in a specific manner and the latest kinds of technologies are used in the preparation of this equipment. The recent mode of technology which is widely used in running of the processing machine of scrap is the hydraulic power.

Types of Scrap Processing Machine

The equipments which are used for scraping the metals have a variation in types. They are prepared in different ways which serves the different purposes of scraping the metals in a proper manner. The variations in the machines are mainly created by the types of cutters which are used. The most commonly used cutters for the scrap processing machine are:

The single shaft cutter

The cutter with Double shaft

The cutter with three shafts

The four shaft cutter

The speed of the scraping machine also varies and differs on the basis of the speed in addition to the number of shafts the power of a machine is determined. The different types of processing machines for scarp which are available in the market are manufactured keeping in mind the varieties of scraps which need to be proccessed for recycling.

The entire process of recycling using the processing machine of scrap material

Scraping is such a process which takes a few steps and the first step is to choose the materials and put it in the right kind of scrap in the chosen machines. Then the metals are scraped. During the process of scraping the machines optimizes the process so that the maximum about of metals can be scraped in an effective manner to be reused. After the process is completed the scraped metal is taken out and the residue is again processed and then cleared from the machine. This is how a basic scrap processing machine works and helps in melting down the unused metals to be used again and again.

This typical form of machine plays a key role towards giving new shape to scrap items to make it reusable to the people.

About the Author : Khaidem Rajit – social media analyst and content writer for Advance Hydrau-Tech Pvt. Ltd. The company is well-known for maunfacturing all types of Scrap Processing Machines such as Baling Machines, Metal Shredders, Shearing Machines, Paper Baler , Briquetting Machines, Fodder Block Making Machines etc.He can be found on Twitter here